-

Engineering Design

Existing concentrators often have issues that impact their profitability, such as improper process set up, mismatched production equipment, unreliable and unstable production lines, low automation, and continued use of outdated technology despite changes in mineral component.

HZE will dispatch a specialized crew to the location to meet the requirements of the owner. An assessment will take place to identify the existing needs, and then steps to improve efficiency and reduce production cost are put into action. A plan of action is implemented to maximize the potential outcome.

HZE, a team with design expertise in the mineral processing industry, has been responsible for multiple international projects, categorized as:

- Crushing and grinding plants;

- Heap, vat and cyanide leaching plants for gold and silver;

- Placer gold concentrator;

- Gold and silver desorption, electrowinning and smelting plants;

- Flotation plant;

- Reselection plant;

- Mineral concentration, dehydration and water recovery plants;

- Recovery of tailings resources;

- Mobile modular concentrators.

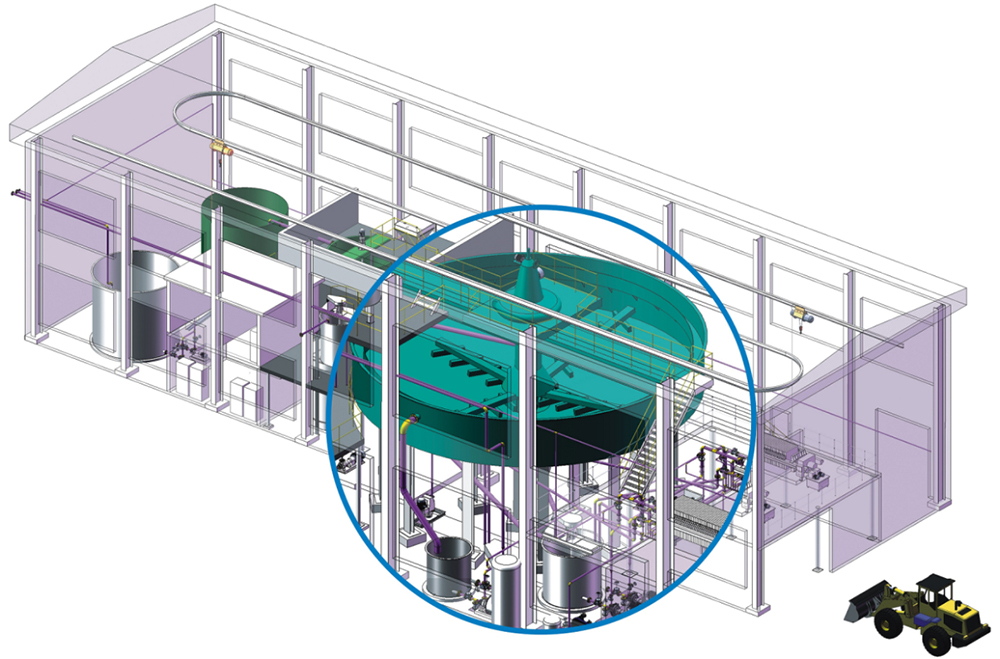

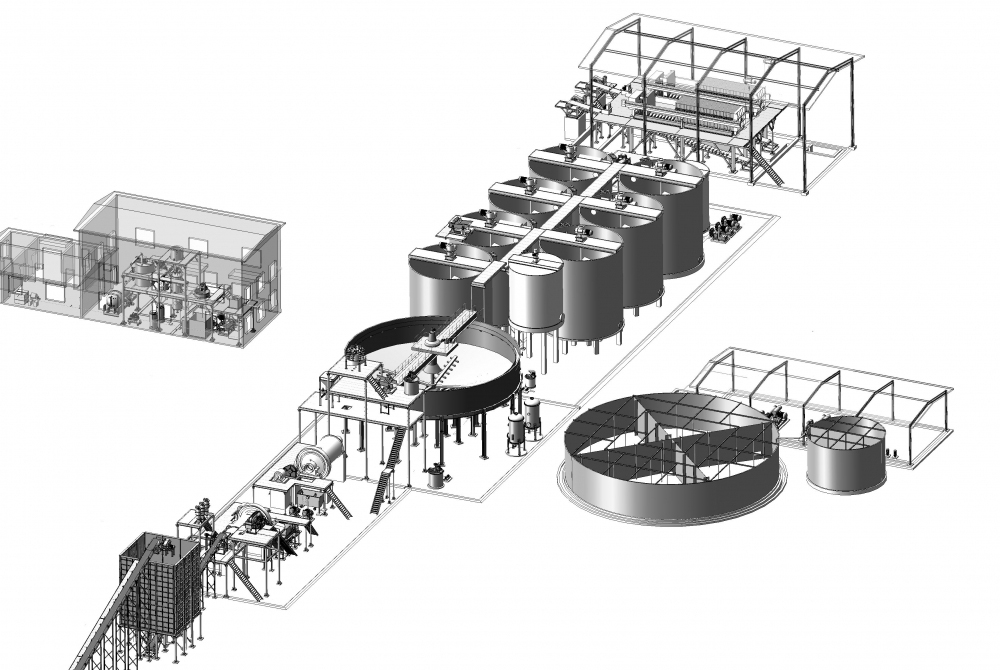

The use of 3D design software is fully incorporated into our design to help facilitate communication during the project execution, consequently reducing costs, shortening the construction timeline, and optimizing efficiency while avoiding any oversights.

The three stages of engineering design are as follows:

Scheme design

Process Flow Diagram (PFD)

Process Control Diagram (PCD)

Process instructions

Material balance sheet

List of process equipment

Process data sheet

Sketch layout

Design documents of each discipline

Preliminary design

Process Flow Diagram (PFD)

Process Control Diagram (PCD)

Piping and Instrumentation Diagram (PID)

Design specification (including each discipline)

List of process equipment

General arrangement drawing

Requisition documents

Equipment layout (zoning)

Piping plan (zoning)

Structure connection diagram

Electrical single line diagram

Automation single line diagram

Construction drawing design

Detailed process layout

Detailed piping diagram

Civil design drawings

Instrument design drawing

Electrical design drawings

Automated design drawings

Fabrication drawings of structural members

Manufacturing drawing of non-standard equipment

Other drawings and documents required for construction

Ask our engineers and designers who are always here for you.