-

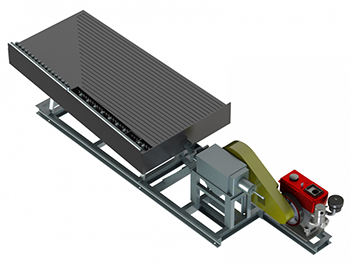

Hammer Mill

Driven by the diesel engine or electric motor, the hammer mill is fixed on the steel frame. The main component is the rotor with hammers and the rotor is comprised of the main shaft, disc, pins and hammers. In the crushing area, the motor leads the rotor to rotate at a high speed. Oores of -50mm and water enter the crushing region via the top inlet. Comminution is done by blowing, smashing, shearing and grinding, done by hammer at a high speed. A sieve plate is placed under the rotor, through which undersize particles and water are discharged.Oversize particles will be left on the plate for further crushing and grinding, at last discharged out of the chamber.

- Easy to install, replace wear pars and operate

- Compact structure to be formed a modular plant with other equipment easily.

- The hammer mill can be driven by the electric motor or diesel engine according to the customer's demand.

- The material of hammers is wear-resisting alloy steel for long service life and reliable running.

- The hammer mill works for fine particles which is useful for good gold recovery.

- The opening slots of the wear-resisting sieve plate are cut by the laser cutter. The aperture can be 0.2mm, 0.3mm, 0.4mm, 0.5mm, 0.6mm, 0.8mm, 1.0mm, 1.5mm or 2.0mm for good gold liberation. This advantage supports the hammer mill to replace the ball mill or rod mill for the artisanal small scale gold miners to recover gold as much as possible.

The hammer mill can crush the ores from less than 50mm to the proper size to liberate free gold fully which is suitable to recover free gold particles and nuggets by the shaking table, concentrator or sluice box.

| Model | Capacity (t/h) | Feeding Size (mm) | Discharging Size (mm) | Driving Options | |

| Eletric Motor (kW) | Diesel Engine (HP) | ||||

200×500 | 1-2 | < 50 | -1.8 | 15-18 | 24 |

300×500 | 3-6 | < 50 | -1.8 | 18-22 | 30 |

400×600 | 5-10 | < 50 | -1.8 | 25-30 | 45 |

We are ready to assist mineral processing operations globally. If you require more information, kindly submit an inquiry below: