-

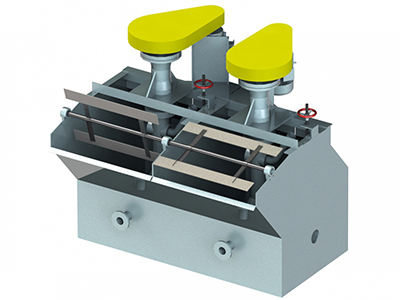

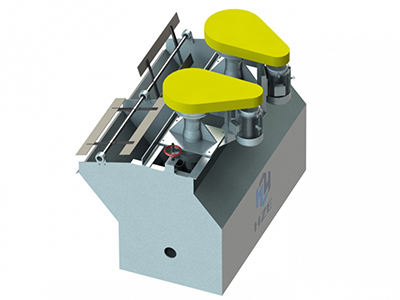

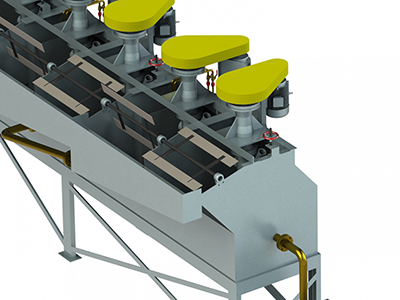

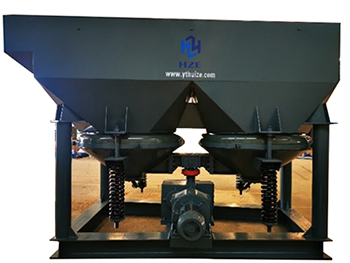

Self Aspirated Flotation Cell

Flotation cell (froth flotation) is receiving an ever-increasing application in mineral processing and chemical industries. The flotation machine is applied as a concentration machine by large, medium, and small size mineral processing plants for the recovery of metal minerals, including gold, silver, copper, lead, zinc, nickle, manganese, iron, molybdenum, tungsten and non-metallic minerals, including barite, quartz, graphite, feldspar and fluorspar.

Working Principle

When the impeller rotates, the centrifugal force generated will push the ore slurry (pulp) of the impeller zone all round, creating a vacumm region. Meanwhile, the upper slurry circulation is formed after the ore slurry is sucked in the upper impeller zone through the circulation hole on the cover; and the lower slurry zone is formed as the slurry flows to the bottom center. Later, the air is sucked into the upper impeller zone through the suction pipe and mixed with the ore slurry there, forming a blanket of bubbles. Having been stabilized, the bubbles overflow the froth launder in the flotation cell and become mineralized bubbles. Then the bubbles rise to the surface of the froth layer and become froth products by the scraper.

- This self-aspirated flotation cell is equipped with backward-inclined two-sided impeller blades that enable the double circulation of the ore slurry inside the flotation cell;

- The wide gap between the impeller and the cover provides much room for air suction;

- Mechanical agitation, and self-aspiration of air and ore slurry;

- The self-aspirated flotation cell can be integrated with other types of flotation cells to be a united set serving as a suction cell for individual operations.

| Model | Effetive Volume (m3) | Capacity (m3/min) | Impeller Diameter (mm) | Impeller Speed (r.p.m) | Agitator Power (kW) | Scraper Power (kW) |

SF-0.37 | 0.37 | 0.2-0.4 | 300 | 352-442 | 1.5 | 0.55 |

SF-0.7 | 0.7 | 0.3-1.0 | 350 | 336 | 3 | 1.1 |

SF-1.2 | 1.2 | 0.6-1.2 | 450 | 312 | 5.5 | 1.1 |

SF-2 | 2 | 1.5~3 | 550 | 280 | 11 | 1.5 |

SF-2.8 | 2.8 | 1.5-3.5 | 550 | 280 | 11 | 1.5 |

SF-4 | 4 | 2.0-4 | 650 | 235 | 15 | 1.5 |

SF-6 | 6 | 3~6 | 760 | 191 | 30 | 2.2 |

SF-8 | 8 | 4.0-8 | 760 | 191 | 30 | 2.2 |

SF-16 | 16 | 5.0-16 | 850 | 169-193 | 45 | 1.5 |

SF-20 | 20 | 5.0-20 | 850 | 186 | 45 | 1.5 |

We are ready to assist mineral processing operations globally. If you require more information, kindly submit an inquiry below: